BFA 60# sandblasting abrasive brown fused alumina price

1 Description

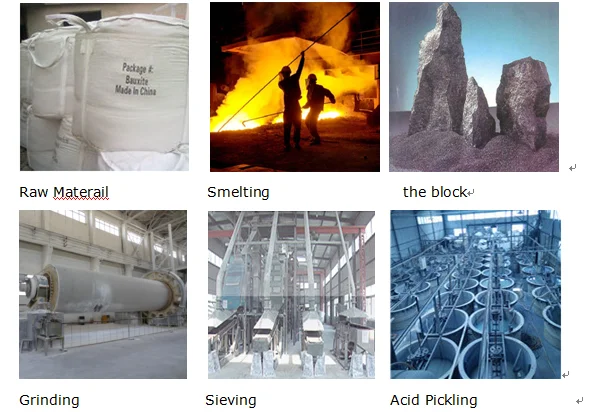

Brown Fused Alumina (BFA) is produced by a reduction fusion of high quality bauxite in electric arc furnaces.It is both a hard and tough material with high strength, making it an excellent abrasive grain for applications. Such as grinding wheels, sandpaper, blasting media, metal preparation, lapping, polishing, and grinding. Its thermal properties make it an excellent raw material for refractory applications.

2 The physical and chemical analysis:

Chemical compositions | Physical properties | ||

Items | Value of specification (%) | Items | Property |

Al2O3 | 94% | Color | Brown |

SiO2 | 2.0%max | Bulk density | 1.53-1.99g/cm3 |

TiO2 | 1.5%-3.8% | Specific gravity | 3.95g/cm3 min |

Fe2O3 | 0.5%max | Morse hardness | 9.0 |

3 Different size of our brown fused alumina (BFA):

type | SIZE |

sand | 8-5mm, 5-3mm, 3-1mm, 0-1mm |

fines | 100#-0 200#-0 320#-0

|

grit | 12,14,16,20,24,30,36,40,46,54,60,80,100,120,150,180,200,220, (#) |

powder | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 240#, 280#, 320#, 360#, 400#, 500#, 600#, 800#, 1000#, 1200#, 1500#, 2000#, 2500# F230 F240 F280 F320 F360 F400 F500 F600 F800 |

4 Packaging & Delivery

Packaging Details:

25 kg in poly-bag, 1000 kg in a big bag

Delivery Time:

Shipped in 7 days after payment

1). Abrasive: Produce ceramic gring wheel, resinoid gringding wheel, Grinding stone, Gringing block, sand paper, sand cloth, sand belt, polish wax, abrasive paste, coating etc..

2). Refractory material: Mainly used for abrasion and high temperature resiatant, inoxidizable aggregate and filling of shaped and monolithic refractory in steel metallurgy, various industrial stoves, electric furnace etc..

3). Sandblasting abrasive: Mainly used for various material workpieces to decontaminate, derusting, prevent corrosion, remove oxide skin etc..

4). Abrasion resistance ground: Mainly used for non-slip of airport and road, chenmical factory board paving.

5). Precision casting: Investment casting technics of stainless steel and aluminium casting in coating.